I've just acquired an Aoyue 852A+ hot air SMD rework station. It should be able to cope with that chip, with the correct nozzle.

Leon

XS1-L2

-

leon_heller

- XCore Expert

- Posts: 546

- Joined: Thu Dec 10, 2009 10:41 pm

- Location: St. Leonards-on-Sea, E. Sussex, UK.

-

Folknology

- XCore Legend

- Posts: 1274

- Joined: Thu Dec 10, 2009 10:20 pm

@Leon Uh Oh I got geek envy now..

;-)

;-)

-

TonyD

- XCore Addict

- Posts: 234

- Joined: Thu Dec 10, 2009 11:11 pm

- Location: Newcastle, UK

so have I ;)Folknology wrote:@Leon Uh Oh I got geek envy now..

@Leon, where did you buy it from?

-

leon_heller

- XCore Expert

- Posts: 546

- Joined: Thu Dec 10, 2009 10:41 pm

- Location: St. Leonards-on-Sea, E. Sussex, UK.

I got it here:

http://www.pcb-soldering.co.uk/index.ph ... duct_id=37

They seem to have some left.

I'm making some little breakout PCBs for some new Freescale accelerometer samples I've obtained. I'll try it on those.

Leon

http://www.pcb-soldering.co.uk/index.ph ... duct_id=37

They seem to have some left.

I'm making some little breakout PCBs for some new Freescale accelerometer samples I've obtained. I'll try it on those.

Leon

-

lilltroll

- XCore Expert

- Posts: 956

- Joined: Fri Dec 11, 2009 3:53 am

- Location: Sweden, Eskilstuna

The tricky thing is to get good solder connection without killing the chip with to much heat.

A Infraread heating plate might be nice to add heat from the bottom of the PCB. That way you do not need to work so hard with the hot air on the chip.

Or you can open your wallet and by this:

http://www.coopertools.eu/product_image ... dpi_01.jpg

A Infraread heating plate might be nice to add heat from the bottom of the PCB. That way you do not need to work so hard with the hot air on the chip.

Or you can open your wallet and by this:

http://www.coopertools.eu/product_image ... dpi_01.jpg

Probably not the most confused programmer anymore on the XCORE forum.

-

lilltroll

- XCore Expert

- Posts: 956

- Joined: Fri Dec 11, 2009 3:53 am

- Location: Sweden, Eskilstuna

Fron linkers forum

"We have done a trial layout and you can fully break it out in 2-layers using 0.125mm track gap, 0.3mm drill size and 0.5mm pads. The package size is 10 x 10mm so it's quite compact.

"

Cool :D I have seen chinese people (Working with manufacturing of eledtronics) make magical things with hot air + PCB + QFN.

"We have done a trial layout and you can fully break it out in 2-layers using 0.125mm track gap, 0.3mm drill size and 0.5mm pads. The package size is 10 x 10mm so it's quite compact.

"

Cool :D I have seen chinese people (Working with manufacturing of eledtronics) make magical things with hot air + PCB + QFN.

Probably not the most confused programmer anymore on the XCORE forum.

-

TonyD

- XCore Addict

- Posts: 234

- Joined: Thu Dec 10, 2009 11:11 pm

- Location: Newcastle, UK

I don' think my wallet's big enough to afford that :Dlilltroll wrote:...

Or you can open your wallet and by this:

http://www.coopertools.eu/product_image ... dpi_01.jpg

-

lilltroll

- XCore Expert

- Posts: 956

- Joined: Fri Dec 11, 2009 3:53 am

- Location: Sweden, Eskilstuna

Good for you then, that a portable small oven plate also emmits infra red photons. :mrgreen:TonyD wrote:I don' think my wallet's big enough to afford that :Dlilltroll wrote:...

Or you can open your wallet and by this:

http://www.coopertools.eu/product_image ... dpi_01.jpg

Probably not the most confused programmer anymore on the XCORE forum.

-

sjalloq

- Active Member

- Posts: 55

- Joined: Tue Jan 12, 2010 1:49 pm

Where can you get prototype boards made with 5 mil tracks and 0.3mm drills? BatchPCB and Olimex top out at 8 mils and 0.5mm drill size.

Thanks.

Thanks.

-

TonyD

- XCore Addict

- Posts: 234

- Joined: Thu Dec 10, 2009 11:11 pm

- Location: Newcastle, UK

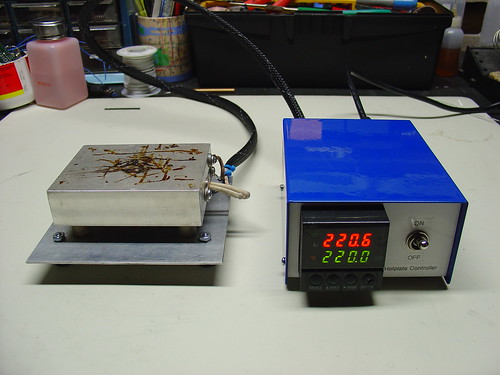

I saw this homemade hotplate at mightyohm which looks like a nice projectlilltroll wrote:...that a portable small oven plate also emmits infra red photons. :mrgreen: