I'm starting a robotics project and I'd like to use the XS1-G4 as the main control processor, however, I have no experience laying out a board for a BGA chip.

Is it even possible to do this with Eagle or Diptrace (the two packages I have; please don't recommend something like Pulsonix or Orcad--this is a hobby project and I don't have a few spare thousand $ lying around)? I know it this will probably require four layers but I've only designed boards with two in the past.

Is there a tutorial or book around that covers designing boards for BGA components that anyone here can recommend? Something that doesn't assume expert-level board design skills would be preferable.

Layout of Board for XS1-G4

-

Jerry

- Member++

- Posts: 30

- Joined: Sat Dec 12, 2009 7:14 pm

- Location: Silicon Valley

-

leon_heller

- XCore Expert

- Posts: 546

- Joined: Thu Dec 10, 2009 10:41 pm

- Location: St. Leonards-on-Sea, E. Sussex, UK.

It is feasible with a low-cost package but it won't be easy; the key is devising an efficient breakout strategy for the BGA pads that also allows the decoupling capacitors to be effective. It's going to be difficult on a four-layer board, six would make things much easier.

-

Andy

- Respected Member

- Posts: 279

- Joined: Fri Dec 11, 2009 1:34 pm

Certainly not a task for the faint hearted. Is a breakout board for the XC1 out of the question? It's possible to stack a board vertically on top with relative ease.

-

leon_heller

- XCore Expert

- Posts: 546

- Joined: Thu Dec 10, 2009 10:41 pm

- Location: St. Leonards-on-Sea, E. Sussex, UK.

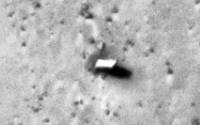

Here is my footprint for the XS1-G4:

Rotating the pads and vias for each quadrant like that means that channels are available for decoupling capacitors. The PCB software I use can create footprints like that automatically in a few seconds. Adding the actual breakout tracks can be tricky if every signal needs to be brought out, but that isn't likely to be required. Some examples are available on the PCB Matrix web site, and need several layers.

Rotating the pads and vias for each quadrant like that means that channels are available for decoupling capacitors. The PCB software I use can create footprints like that automatically in a few seconds. Adding the actual breakout tracks can be tricky if every signal needs to be brought out, but that isn't likely to be required. Some examples are available on the PCB Matrix web site, and need several layers.

-

shawn

- XCore Addict

- Posts: 238

- Joined: Thu Dec 17, 2009 5:15 am

How many layers is the XMP-64 ?

How close, adjacently can one place the G4's, I would guess 6 layer vs 4 would have more consistent thermals.

Technically one could could mount a G4 on top and bottom,

of the same area on PCB, what thermal issues would I have to

deal with considering heat flows from the BGA to the board.

If you want a break out board the more layers the better, of course.

I'm thinking more dense placed chips would help offset the extra multilayer cost's.

How close, adjacently can one place the G4's, I would guess 6 layer vs 4 would have more consistent thermals.

Technically one could could mount a G4 on top and bottom,

of the same area on PCB, what thermal issues would I have to

deal with considering heat flows from the BGA to the board.

If you want a break out board the more layers the better, of course.

I'm thinking more dense placed chips would help offset the extra multilayer cost's.